FracTech Laboratories has been performing a comprehensive range of Rock Mechanics and related testing for nearly 30 years. With state of the art equipment we regularly perform testing programs for operators and service companies globally to answer some of the following questions:

What is the risk of sand failure and production in a reservoir?

Can you help populate our wellbore stability models with mechanical properties in the shales and sands?

Can you provide thermal expansion coefficients coupled with elastic properties to assess the likely of thermal fracturing?

Can you determine reservoir compaction during production through uniaxial compressibility testing?

Can you qualify mechanical properties of cements for field application?

Can you calibrate our logs for hydraulic fracture design and help optimize proppant/fluids?

Can you determine heat transfer properties for modelling thermal effects close to buried structures?

The answer is Yes to all the above and more!

TESTS

Equipment

Extensive facilities including:

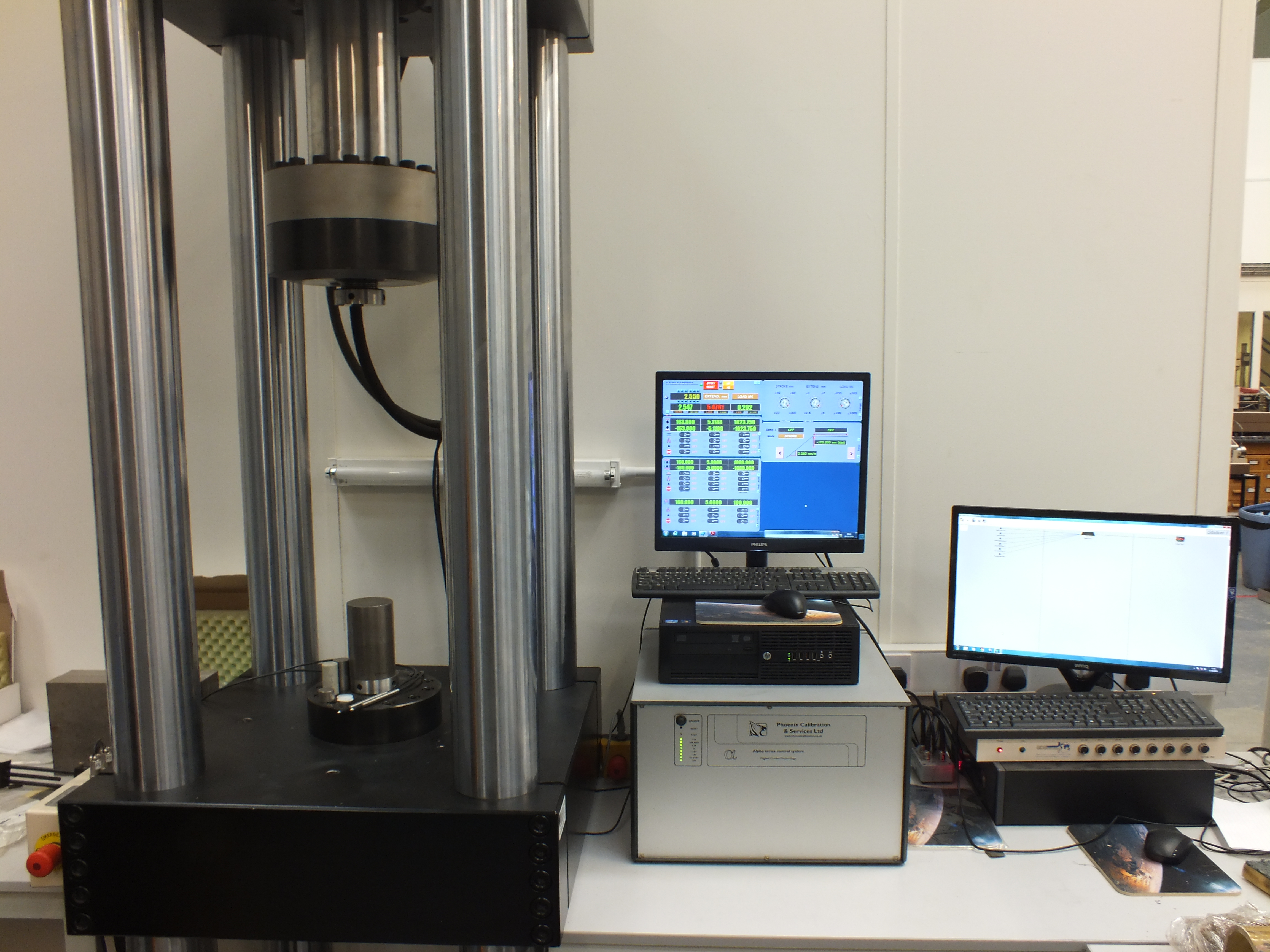

Three servo hydraulic high stiffness test machines with load/displacement control

1000kN

Radial stress/pore pressure to 100MPa (14,500psi); P, S1, S2 acoustics

Temperature to 150 Celsius

Advanced TWC set up to 4" OD, 8" long with Canty imaging of solids production

Full in-house coring and sample re-preservation facilities

Sample Quality

A key feature of Rock Mechanics testing at FracTech is the focus on sample preparation. Special mills are used to prepare samples to ensure they are very precise cylinders free of imperfections. Good rock mechanics data is built on sample quality and FracTech is known in the industry for this attention to detail. Various cutting fluids are available and samples can be CT scanned before testing.